The machine adopts hydraulic driving system and they are the latest iron workers in our country, various metal plate, square bar, Round bar, angle, channel and joist can be cut, punched and notched on the machine. It is also equipped with a stop device for cutting.

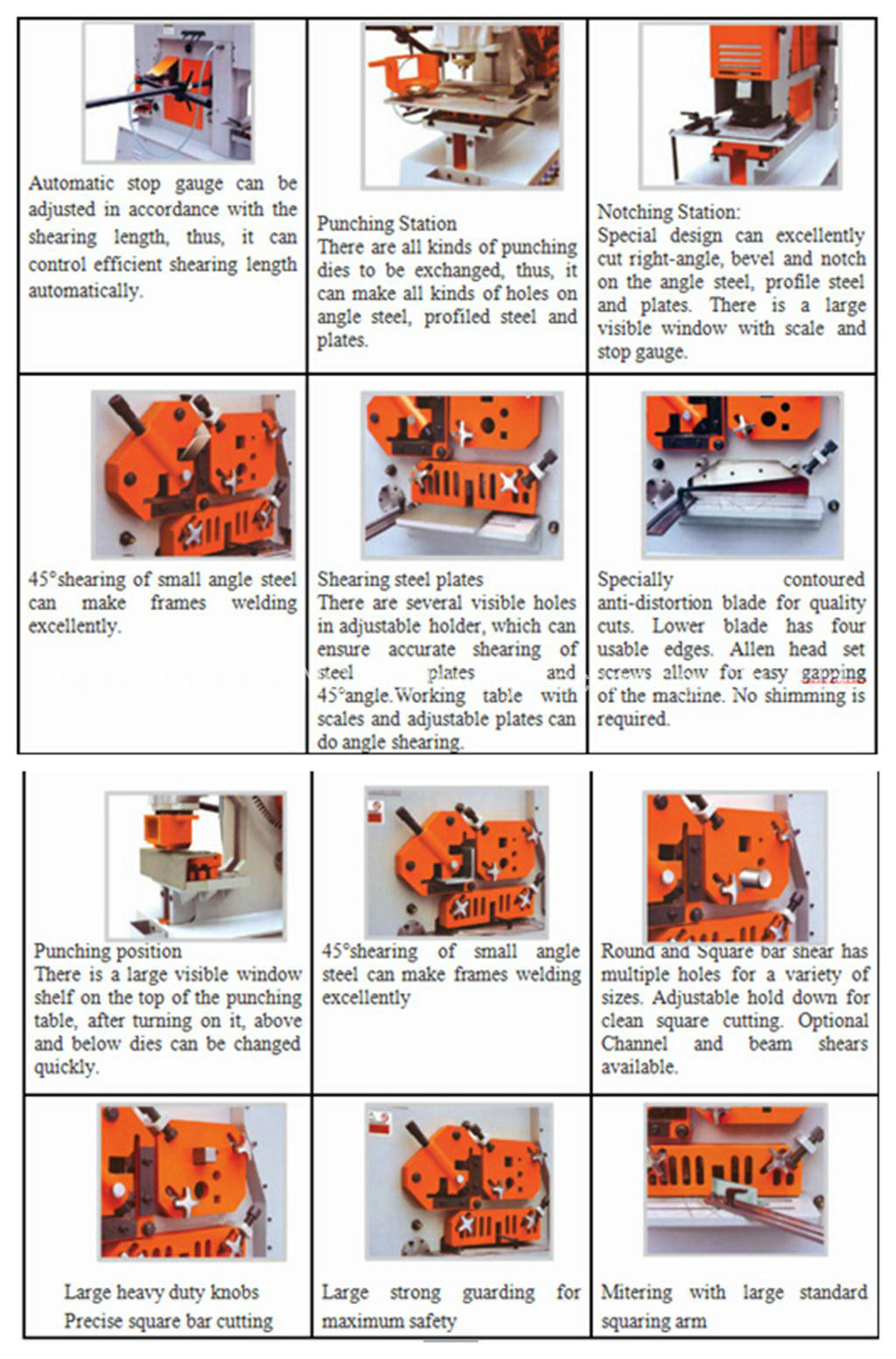

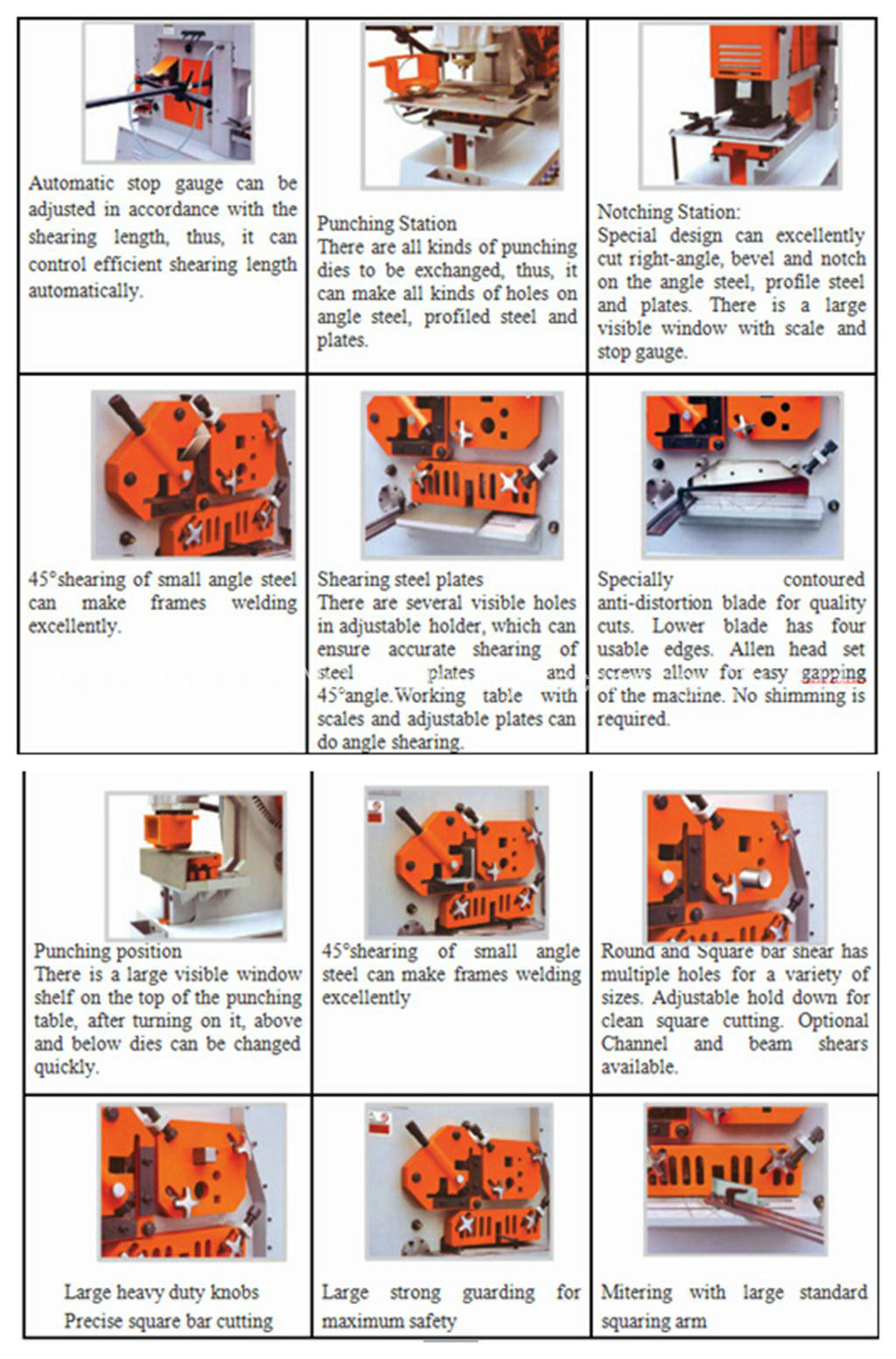

Products Station

Main standard properties components supply along with the Ironworker:

1. All the electrical parts are with CE certified France Schneider.

2. Professionally engineered design frame structures.

3. Steel welds with high precision strength and rigidity to eliminate vibrations.

4. Seven sets of tools, including punching and blades were installed on the machine, punches size customised for free.

5. Oil seals by Japanese, NOK.

6. Double independent hydraulic cylinders

7. Double Foot pedal controlled work separately

8. Indicator on both hydraulic cylinders

9. Large notching table with Ruler guide

10. Large flat shearing table with Ruler guide

11. Large punching table with ruler guide

12. Easy Adjustable stroke control with ruler

13. Electric back gauge with auto stop

14. Movable working light for placing at any desired position

15. Hydraulic system with overload protection system

16. Emergency safety stop switch

17. Easy to maintenance and Five Year Quality Warranty for free,flexible extended warranties if needed.

Our Services:

1 Standardization of Service "112"

1: Expect a response in 1 hour

1: a solution will be provided in 1 day

2: We will fix the issue in 2 days

2. Installation Service

Installation Services are available for HACOL machinery with disassemble machine. We dispatch technicians to customers' locations for installation and configuration of machines.( Customers only need to afford technician airfare and lodging)

3. Training Service

Our technicians are available to visit your factory and offer comprehensive training of how to operate our CNC machines. You may also send your technician to our facilities to undergo a more rigorous training program.

4. Quality Guarantee

1.All HACOL machines quality are in guarantee and produced according to the agreed technical data.

2. Each machine will be performed a final test after production and before shipment. We run the machines for a few days, and then use it under similar conditions that the customer will be using. After making sure the machines is performing properly, we will then make the shipment.

3.Each unit machine has a FIVE year warranty.

| Profile | Round Bar(mm) | Square Bar(mm) | Equal Angle(mm) | T Bar(mm) | Joist(mm) | Channel(mm) | ||

| 90° Shearing | 45° Shearing | 90°Shearing | ||||||

| Section view | ||||||||

| Q35Y-16 | 45 | 40*40 | 125*125*12 | 70*70*8 | 120*120*12 | 126*74*5 | 126*53*5.5 | |

| Q35Y-20 | 45 | 45*45 | 140*140*12 | 70*70*10 | 140*140*124. | 160*86*6 | 160*60*6.5 | |

| Q35Y-25 | 60 | 50*50 | 160*160*14 | 80*80*7 | 160*160*14 | 200*102*9 | 200*75*9 | |

| Q35Y-30 | 65 | 55*55 | 180*180*16 | 80*80*10 | 180*180*16 | 280*124*10.5 | 280*86*11.5 | |

| Q35Y-40 | 75 | 60*60 | 200*200*16 | 100*100*10 | 300*120*18 | 120*280*16 | 300*92*12 | |

| Q35Y-50 | 80 | 65*65 | 200*200*20 | 120*120*10 | 300*300*18 | 300*300*16 | 300*92*12 | |

| Technical Parameter Table | ||||||||||||

| Model | Punching Pressure (T) | Max. cutting Thickness of Steel Plates (mm) | Plate Strength (N/mm²) | Angle of Shear (°) | A trip size (T*W)(mm) | Slider trip (mm) | Strokes (min-1) | Throat Depth (mm) | Punch Depth (mm) | Max. punching diameter (mm) | Main Motor (kw) | Qverall Dimenesions (L*W*H) |

| Q35Y-16 | 60 | 16 | ≤450 | 7 | 16*250 8*400 | 80 | 9--25 | 300 | 16 | 25 | 4 | 1640*730*1770mm |

| Q35Y-20 | 80 | 20 | ≤450 | 8 | 20*330 10*480 | 80 | 10--28 | 355 | 20 | 30 | 5.5 | 1860*800*1900mm |

| Q35Y-25 | 115 | 25 | ≤450 | 8 | 25*330 16*600 | 80 | 9--18 | 400 | 25 | 35 | 7.5 | 2335*960*2090mm |

| Q35Y-30 | 145 | 30 | ≤450 | 8 | 30*335 20*600 | 80 | 7--16 | 600 | 30 | 38 | 11 | 2680*1040*2300mm |

| Q35Y-40 | 200 | 40 | ≤450 | 8 | 35*400 25*700 | 80 | 10 | 600 | 40 | 40 | 15 | 2770*1240*2350mm |

| Q35Y-50 | 250 | 50 | ≤450 | 8 | 40*400 30*750 | 80 | 10 | 600 | 50 | 40 | 18 | 3000*1440*2450mm |

| The data listed in this table as a reference data, such as with the machine actual match, should be based on the actual machine data. The Company reserves the right of final interpretation of this data sheet | ||||||||||||

Main standard properties components supply along with the Ironworker:

1. All the electrical parts are with CE certified France Schneider.

2. Professionally engineered design frame structures.

3. Steel welds with high precision strength and rigidity to eliminate vibrations.

4. Seven sets of tools, including punching and blades were installed on the machine, punches size customised for free.

5. Oil seals by Japanese, NOK.

6. Double independent hydraulic cylinders

7. Double Foot pedal controlled work separately

8. Indicator on both hydraulic cylinders

9. Large notching table with Ruler guide

10. Large flat shearing table with Ruler guide

11. Large punching table with ruler guide

12. Easy Adjustable stroke control with ruler

13. Electric back gauge with auto stop

14. Movable working light for placing at any desired position

15. Hydraulic system with overload protection system

16. Emergency safety stop switch

17. Easy to maintenance and Five Year Quality Warranty for free,flexible extended warranties if needed.

Our Services:

1 Standardization of Service "112"

1: Expect a response in 1 hour

1: a solution will be provided in 1 day

2: We will fix the issue in 2 days

2. Installation Service

Installation Services are available for HACOL machinery with disassemble machine. We dispatch technicians to customers' locations for installation and configuration of machines.( Customers only need to afford technician airfare and lodging)

3. Training Service

Our technicians are available to visit your factory and offer comprehensive training of how to operate our CNC machines. You may also send your technician to our facilities to undergo a more rigorous training program.

4. Quality Guarantee

1.All HACOL machines quality are in guarantee and produced according to the agreed technical data.

2. Each machine will be performed a final test after production and before shipment. We run the machines for a few days, and then use it under similar conditions that the customer will be using. After making sure the machines is performing properly, we will then make the shipment.

3.Each unit machine has a FIVE year warranty.